Our featured boat for January 2026 is one to look out for as the year unfolds. She’s ‘Raedwald’, a brand new modern dinghy designed and built in Suffolk by local young boatbulder, Sam Doman. In this first part, we let the photos tell the build story. Part 2 sees ‘Raedwald’ on her first sea trials.

What influenced the design for ‘Raedwald’?

As a boatbuilder and sailor, I often found myself wondering what my ideal do-it-all boat would look like. With a background in high-performance sailing, passion for traditional boats and love for dinghy cruising; the ideal boat needed to be versatile, fast, beautiful, seaworthy and capable. As I refined the design in my head over the past few years, a clear hull shape developed. Essentially the boat is a fairly traditional 15’3″ clinker dinghy above the water line, while the underwater shape is powerful and efficient with a fine entry and low drag lines. Wide, flat mid sections encourage planing, making the boat inherently stable. This form should also be very sea kindly, with a high bow and plenty of freeboard to keep you dry in a North Sea chop. To make the boat as versatile as possible, she has two mast steps and the option of five rig configurations, suiting everything from singlehanded cruising to high-performance racing.

How was ‘Raedwald’ built?

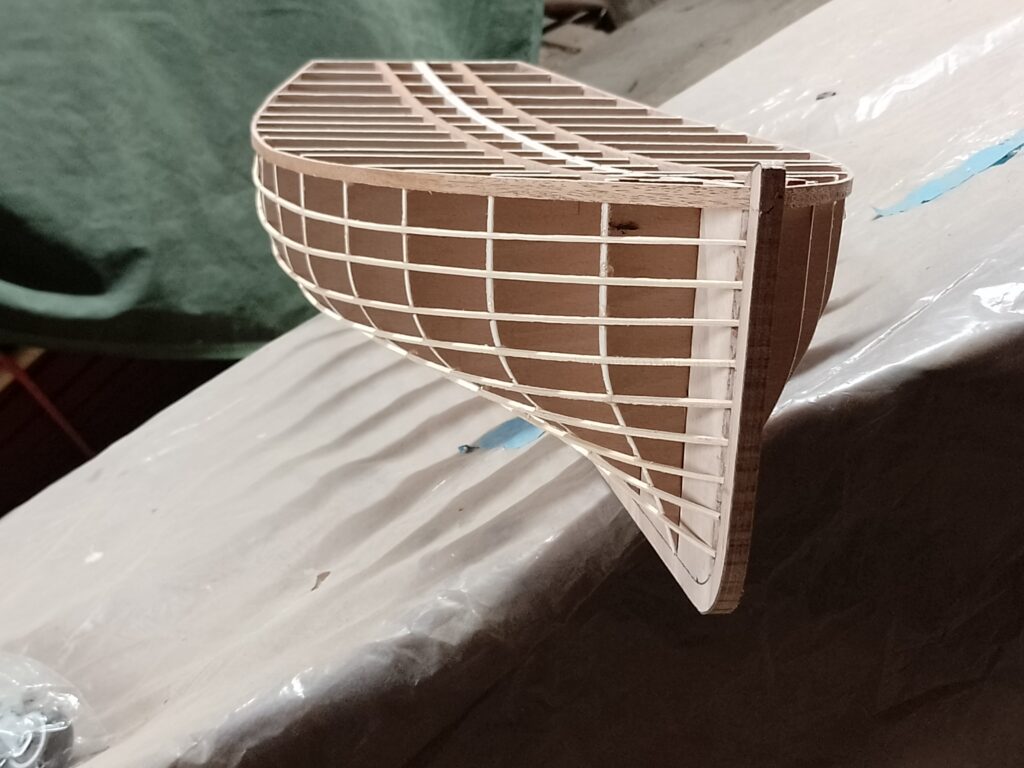

I have no background or training in boat design, but having sailed many and varied boats throughout my life, I’ve developed a pretty good feel for how different hull shapes move through water. I knew it was possible to make a boat that looked like a traditional clinker workboat, but was capable of performance on a par with any modern racing dinghy. Not knowing how to translate this into a two dimensional drawing, I made a series of scale models to refine the shape, before scaling up to a full-size half model, which I used to make the building frames from. The prototype hull is clinker, built in marine plywood, glued with epoxy and reinforced with carbon fibre and fibreglass. I decided to incorporate this juxtaposition of modern materials and traditional design into the aesthetic of the boat, leaving the sheer plank, transom and knees as exposed carbon fibre, contrasted against the oiled oak and sapele gunwales, thwarts and trims. As building a one-off boat is such a huge amount of work, I decided it was worth taking a series of moulds from the prototype hull. Future copies may be produced in GRP. The finished prototype weighs about 170kg, but I think we can get the production boats down to below 150kg, whilst maintaining a very robust and rigid cored-fibreglass hull construction.

Aboard ‘Raedwald’

The interior is carefully designed to maximise space in the ergonomic cockpit. She has a huge amount of built-in buoyancy, a completely self-draining design (even in the unlikely event of the boat being entirely swamped) and optional water ballast compartments. These add a total of 70kg either side of the centreboard case, making the boat virtually impossible to capsize (even if you’re really trying!)

If you are interested in finding out more, or having a fibreglass boat built, please contact Sam by email.

Words and photos: Sam Doman

www.modernclassicboats.com

You must be logged in to post a comment.